In the world of concrete construction, the choice of formwork is crucial. It directly affects the speed, safety, and cost of a project. Traditionally, contractors have relied on timber, plywood, or metal systems. But in recent year, ABS plastic formwork has emerged as a modern alternative that delivers both durability and efficiency.

So, what makes ABS formwork such a powerful solution? Let’s explore how this material is changing the game for contractors and developers alike.

ABS (Acrylonitrile Butadiene Styrene) is a strong and durable material that is also versatile. It’s commonly used in automotive parts, consumer electronics, and now—thanks to its impressive structural performance—in the construction industry as a formwork material.

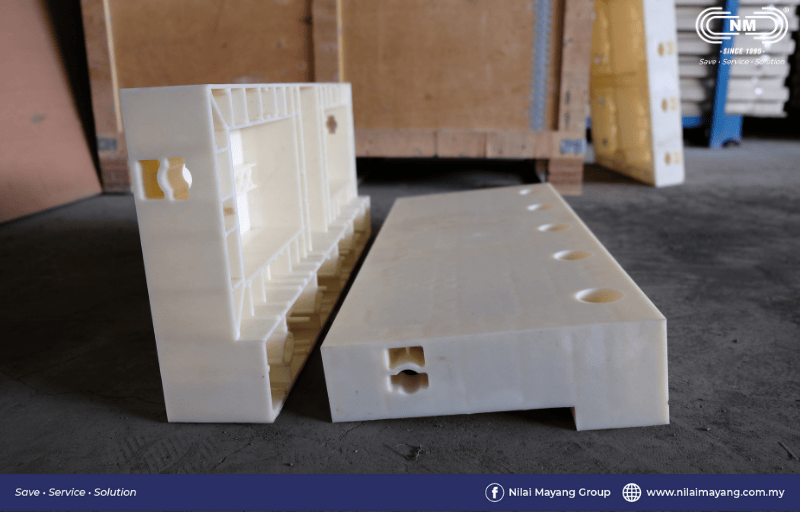

ABS formwork panels are engineered to withstand the rigors of repeated concrete casting while remaining lightweight, easy to handle, and reusable. This blend of resilience and practicality makes it a top choice for modern building projects.

One of the biggest advantages of ABS formwork is its exceptional durability. Unlike traditional timber formwork, which can warp, absorb moisture, or deteriorate after a few uses, BS panels maintain their shape and strength even after dozens—if not hundreds—of cycles.

Durability is only half the story. ABS formwork also brings significant efficiency gains that directly improve workflow on construction sites:

Lightweight & Easy to Handle: Unlike steel or timber panels, ABS formwork is much lighter, allowing for quick assembly and dismantling—often with just one or two workers.

Modular Design: Many ABS systems are designed with modular locking components that snap or slot together easily, minimizing the need for tools and reducing labor time.

Smooth Finish: The plastic surface creates a clean, consistent concrete finish that reduces the need for additional surface treatment or rework.

High Reusability: Some systems offer 100+ reuses, maximizing the return on investment over multiple projects.

When every hour counts, these benefits translate into real project value: faster turnover, fewer labor hours, and better results.

Using ABS formwork also supports sustainability goals. Since the material is reusable and recyclable, it significantly reduces construction waste compared to disposable plywood systems. Additionally, by lasting longer and requiring less maintenance, ABS formwork lowers material consumption over time, contributing to greener and more economical construction practices.

ABS plastic formwork combines the toughness needed for structural demands with the practical efficiency today’s job sites require. It’s a solution that empowers contractors to build faster, safer, and more sustainably—all while keeping long-term costs under control.

Contact

© 2021 Nilai Mayang | Web Design by Webmore

All Rights Reserved By Nilai Mayang Engineering Sdn Bhd (Registration Number: 199601012529)

WhatsApp us